Product name: SK coal transmission program control system

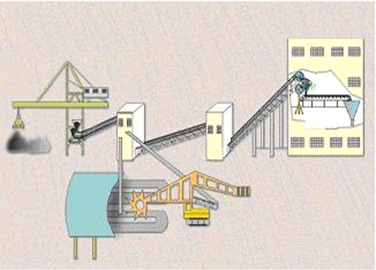

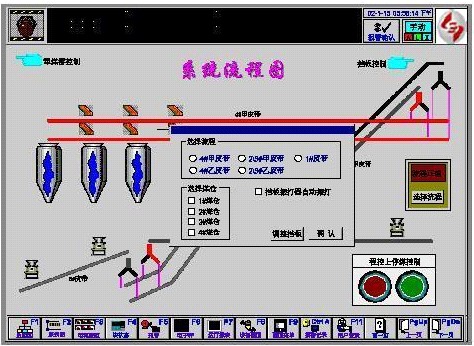

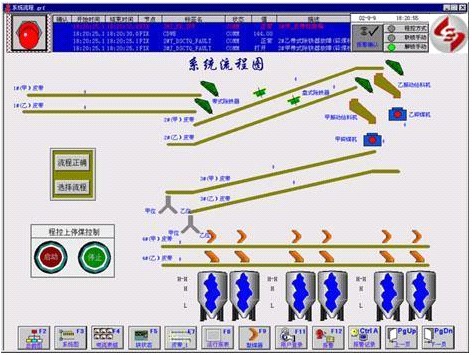

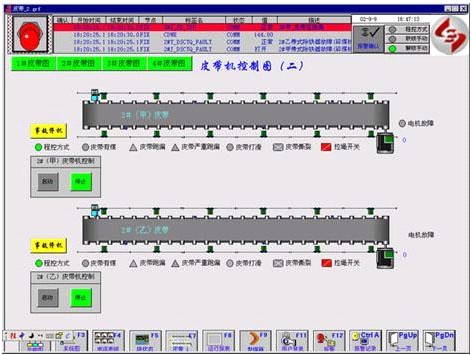

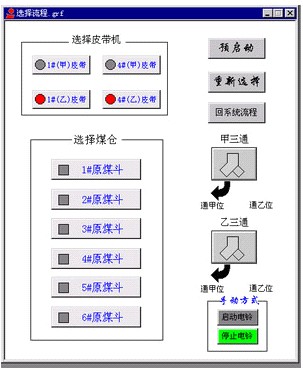

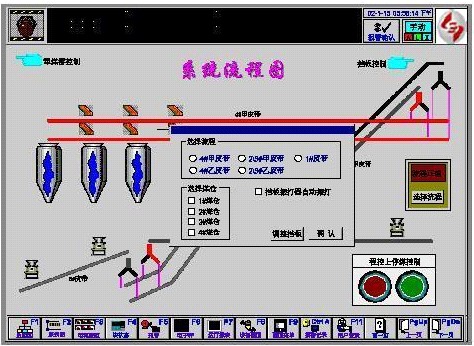

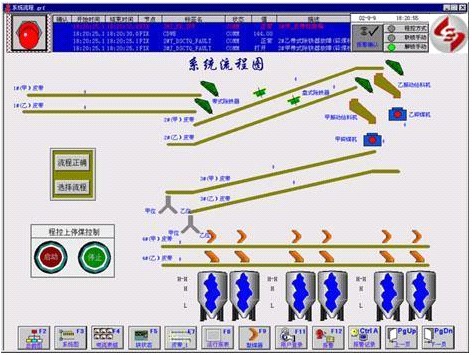

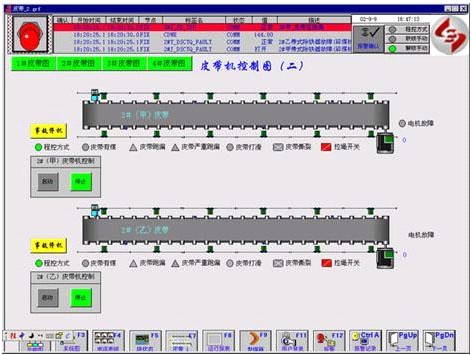

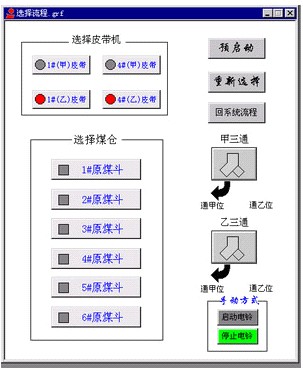

SK coal conveying program control system is composed of programmable controller (PLC), industrial control computer, field control monitoring equipment and industrial television monitoring system. It has successfully realized the automation of coal conveying and blending in the coal conveying system, providing users with a safe, stable, efficient and coordinated operating environment of the coal conveying system. SK coal transmission program control system has a variety of perfect functions, the overall control system constitutes the belt automatic coal loading, coal bunker automatic coal blending, furnace metering, computer monitoring and management, screen display process, operating parameters screen prompt, language alarm, broadcast call, printing tabulation and other functions. Can be achieved for the coal conveying system includes belt machine, crusher, impeller coal feeder, coal plough, tee frame, belt said, in addition to iron, speed signal, wandering signals, pull switch, coal flow, blocking signals, tearing, coal bunker coal level signals, dust collector, such as vibration DaQi equipment control and monitoring. The control system adopts double-machine thermal standby, and the communication between PLC main station and sub-station adopts double-cable redundancy. SMK control system is applicable to power plant coal conveying systems with various installed capacity and different layout types, and also applicable to mining areas, wharfs, grain stations and other use occasions for mine conveying, materials and grain conveying.

The system has: coal transport mode selection, program control start and stop belt, automatic coal blending warehouse; Display of coal level history curve records, automatic alarm and automatic diagnosis of equipment faults; Realized the field information collection, processing, operation display, equipment life management, printing tabulation and other perfect production management functions. The system also has an industrial television tracking display and network communication with DCS and MIS systems.

Main features:

• the hardware and software are designed in accordance with the new horizontal design at home and abroad

• the key equipment adopts foreign advanced equipment

• modular hardware and modular software

• realize the whole process automatic control of coal transmission and distribution system

• manual function is set for emergency handling

• the upper management machine adopts double-machine thermal standby

• PLC adopts double-machine redundancy, and the communication is double-cable communication

• with uninterruptible power UPS and dual interface power supply

• networking with DCS and MIS

• the TV monitoring system is equipped with an anti-theft alarm system

Main functions:

• program control of coal feeding system

• program control of coal handling system

• program control of coal blending system

• fault monitoring and protection interlocks

• automatic selection and simulation of operation mode

• run/overhaul setup, one-step/program-controlled operation

• conditional blending and time blending

• automatic low position loading and forced loading

• coal loading statistics and boiler metering

• management of coal level history records in coal bunker

• equipment life history management

• system management printing reports

• voice alarm and broadcast call

• automatic system fault analysis and processing

• industrial television monitoring of coal conveying system

• equipment start-stop and fault tracking display video

TEL:133-0520-1772

TEL:133-0520-1772